Description

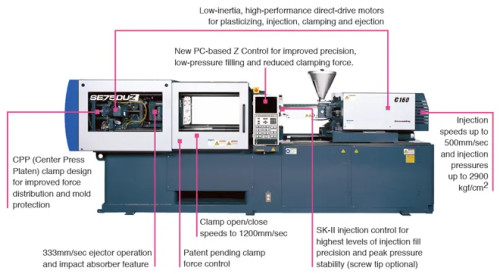

Sumitomo (SHI) Demag’s SE-DUZ direct-drive all-electric injection molding machines, 20 U.S. tons, deliver unmatched precision, high-speed performance, exceptional energy efficiency and increased overall productivity.

[NOTE: The 34 to 198 ton SE-DUZ models have been replaced by the SE-EV-A Series.]

Raising the bar for injection molding machine control, the SE-DUZ is equipped withour Zero-Molding technology, an easy-to-use PC-based control that provides a new level of injection molding precision with low-pressure filling and reduced clamp force. Unique attributes of Zero-Molding include:

- Flow Front Control (FFC) System (patent pending) that optimizes the flow front further allowing control of low internal pressures inside the cavities

- Minimum Clamping Molding (MCM) System which helps avoid flash, burn spots and shorts shots, and can reduce mold wear, cycle time and power consumption

- Simple Process Setting (SPS) System which allows easy setup and operations while helping the operator avoid oversights and mistakes

The SE-DUZ features four direct-drive, Sumitomo (SHI) Demag AC servo motors with full closed-loop control and digital sensors. Plasticizing, injection, clamping and ejection are controlled by these motors, and each motion except plasticizing uses a ball screw. All four motors are beltless, providing superior mechanical efficiency, repeatability and durability, and avoiding the problems associated with belt adjustment and dust.

Unique to Sumitomo (SHI) Demag’s advanced motor technology is a lighter, compact, low inertia design with the best mechanical configuration for each motion. The result is an exceptionally energy-efficient, low inertia system that:

- Provides the high speeds, pressures and torque for the most demanding applications

- Draws power only as it is needed

- Is easier and faster to stop and start

- Provides exceptional precision and repeatability

Other important features and capabilities of the SE-DUZ include:

- Patent-pending clamping force correcting system for constant clamp force control

- Algorithm and software for the servo control that achieves faster response and improved stability

- A wider selection of injection unit/screw combinations

- High-speed, low vibration clamping and a Center Press Platen design

- Wider distance between tie bars

- Specialized features such as synchro-plast and multi-toggle clamp force control are provided as standard

The SK-II advanced injection control is available as an option to help molders achieve the highest levels of injection fill precision and peak pressure stability. (Control software standard; screw tip optional.)

Additionally, the revolutionary SL screw assembly is selectable as a standard option on the SE-EV-A Series. This innovative plasticizing system reduces shear heat, improves molding stability, prevents burn spots and stagnation of the melt in the barrel, and allows exceptionally fast color and/or resin change-out.

The SE-DUZ is backed by a comprehensive Customer Satisfaction Program with Sumitomo’s standard-setting warranty program, worry-free parts, responsive field service and financing availability – plus advantages such as expert processing assistance.

Please use the SE-DUZ links below for more information about this series of all-electric injection molding machines.

SE-DUZ INFO LINKS

→ Overview

→ Clamping

→ Warranty